Learn Engineering

Learn about engineering using our online video courses, 3D models, handbooks, and quizzes.

Over 60 hours of engineering video tutorials

Over 40 engineering courses (text and video based)

Dozens of PDF handbooks

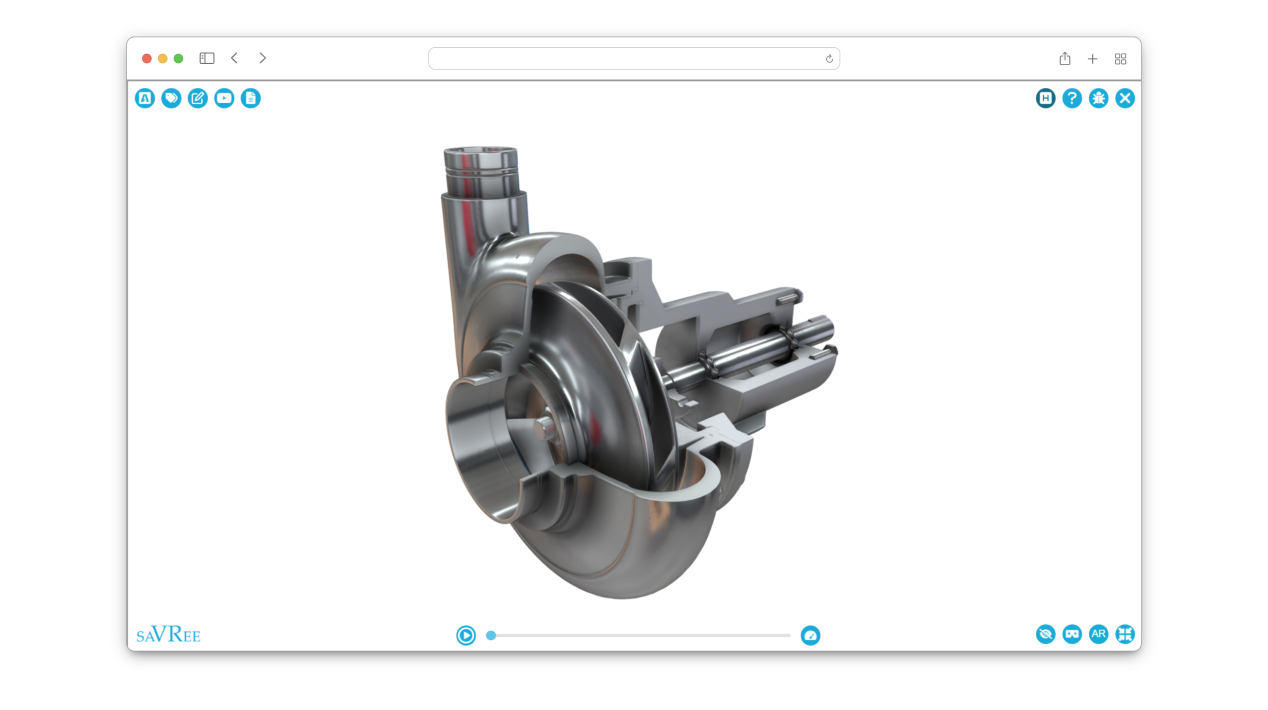

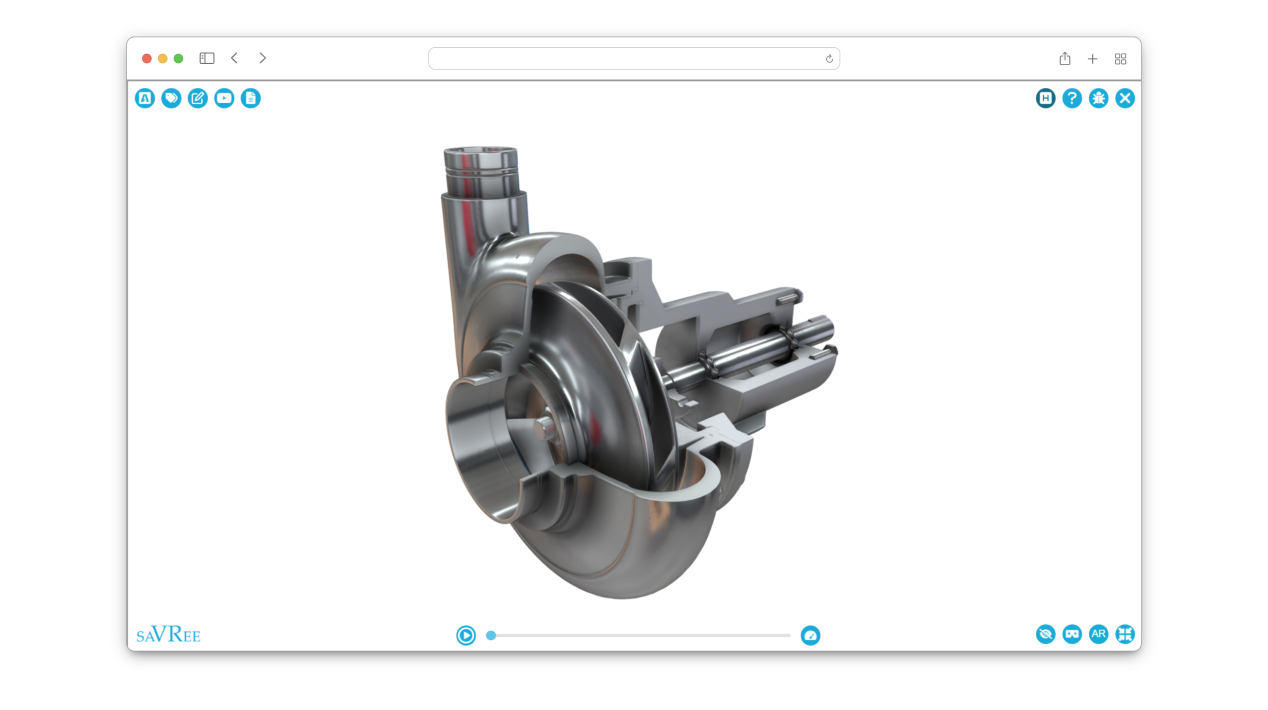

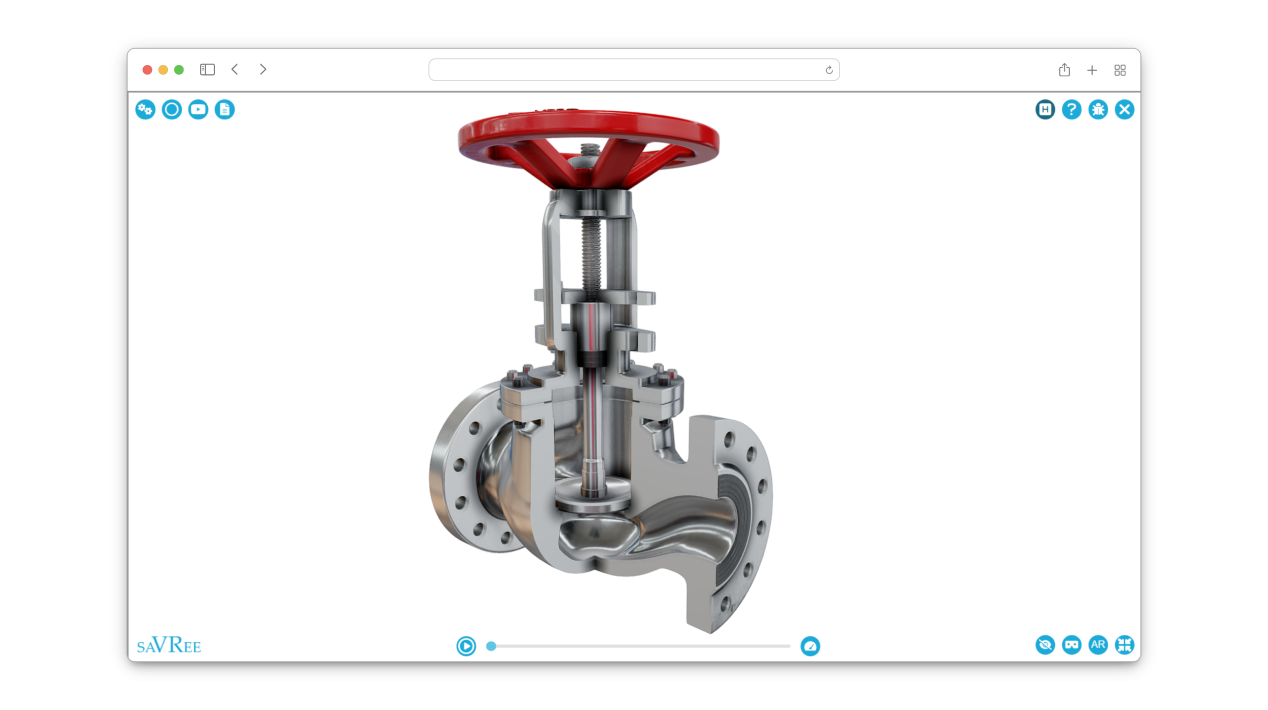

interactive 3D models

hours of training videos

engineering handbooks

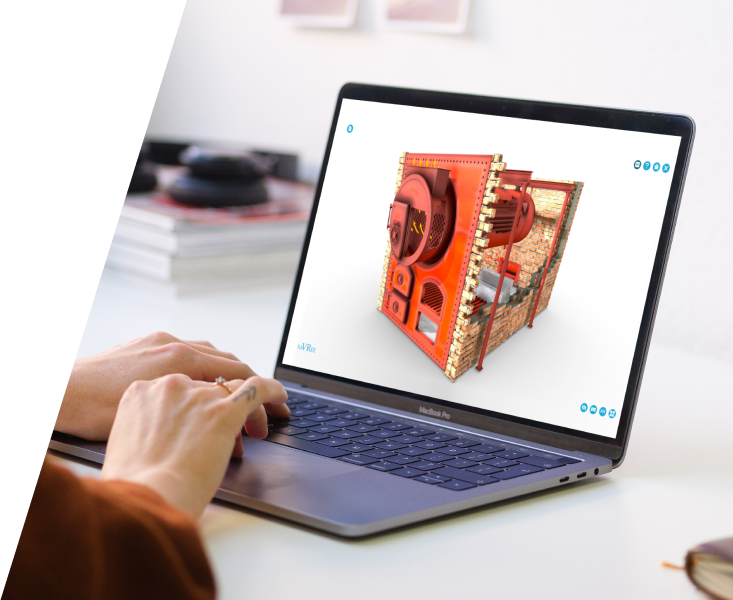

Let saVRee be your trusted partner in engineering training.

Learn about engineering using our online video courses, 3D models, handbooks, and quizzes.

For individuals, organisations and institutions, who wish to instruct/teach with saVRee. Teach engineering using over 400 fully interactive 3D models. Build your own custom 3D interfaces to merge your existing content with saVRee's, embed interfaces within your LMS, and white-label your interface.

Explore saVRee's Enterprise Engineering Training packages. Empower your workforce with the skills and knowledge it needs.

Because individuals, colleges, Universities, and corporations, all trust saVRee to get the best engineering training possible. Check our testimonials!

Since saVRee started in 2017, we have helped over 50,000 online students increase their engineering knowledge.

We have also helped our clients train thousands of their own employees particularly in the HVAC, Mechanical, Marine, Electrical, Automobile, Chemical and Power Engineering industries.

Tried and tested by over 50,000 students!

A wide range of engineering courses and tutorials that grows every month.

Learn more

Over 400 interactive 3D models accessible through a web-browser, in AR, or VR.

Learn more

Our technical encyclopedia has hundreds of articles and over 100,000 words of engineering content.

Learn more